R & D Service

We have our own material formulation engineers, which involve the common rubbers are: styrene-butadiene rubber (SBR), nitrile rubber (NBR), ethylene propylene diene monomer rubber (EPDM), fluorine rubber (FKM), silicone rubber (MVQ/Q), hydrogenated cyanide-butadiene rubber (HNBR), acrylic rubber (ACM), ethylene acrylic rubber (AEM), chloroether rubber (ECO), fluorosilicone (FVMQ), butyl rubber (IIR), polyurethane (PU), neoprene (CR), Perfluoroelastomer (FFKM), natural rubber (NR), etc.

Contact us

Our R & D Capabilities

More than 30 years of experience in the industry and can provide a high level of competence in dealing with our customers’ challenges. We have ample knowledge and skills to successfully conduct a promotion study in the client’s target market, provide suggestions on rubber formula development , or do any other task required by our clients. we have our own CNC machining center, milling machine and CNC lathe, etc., and independent mold design and manufacturing capabilities, as well as all kinds of development software and processing equipment.

Outcomes Driven

We pay great attention to technology and quality. The talent structure is finely differentiated, from the chief engineer, the deputy manager of the technical department to the development working groups.

Professional Test

1. Rubber hardness; 2. Density; 3. Tensile strength; 4. Elongation; 5. Tear strength; 6. Vulcanization characteristics; 7. Infrared spectroscopy; 8. Ash; 9. resilience; 10. Rubber low-temperature brittleness; 11. Hot air aging; 12. Ozone test; 13. Fatigue aging test; 14. Salt spray test; 15. Compression set resistance; 16. Oil resistance; 17. a variety of chemical media; 18. Akron abrasion

International Test methods

1、ASTM D 2000, SAE J200, ISO, GB, DIN; 2、VDA, JIS, VW2.8.1;3、PSA S225106, PSA S226106; 4、55280-05, 55288-08, 55290-04;5、ST0025, ST0026, ST0052, ST0083; 6、UFI 0237, UFI 0219, UFI 0197, UFI 0204;7、TS 0191, TS 0247, TS 0220;8、GMW3083; 9、TL 52329

Design

What is the basic data required for project evaluation (inquiry)?

What information do I need to provide if I want your company to assist with a project evaluation or quotation?

Generally speaking, you need to provide information about the size of the product, the quantity or purchase plan, the physical property requirements of the rubber material, etc. If you have technical drawings of the product or documentation of the physical property requirements of the rubber, it will be of great help in the project evaluation. Of course, in many cases, you may not know how to choose the right rubber material for you, or you may not be sure whether the product you need can be made. That’s okay, all you need to do is contact us. We will assist you in completing the project evaluation and provide you with professional advice free of charge.

Contact us

Formula and Molds Design

More than 30 years of experience in the rubber industry, we can provide a high level of competence in dealing with our customers’ challenges. We have ample rubber knowledge and production experts to successfully meet your technical and cost requirement, provide suggestions on rubber sheet procurement, or do any other task required by our clients.

Formula Analysis

We can analyze the rubber material provided by our clients, then we will design a new formula to meet the required specification. therefore, we make a small batch and test the formula. finally, we give our counter sample for your testing.

Test Report Service

Our lab is equipped with advanced equipment and facility to make most of tests related with rubber and plastic products. We can present you the test report for the product you order from us. we also can provide the test report for your rubber products from any other sources as per your requirement. When you pay the cost, we can provide third party test report from SGS, TUV or any third party.

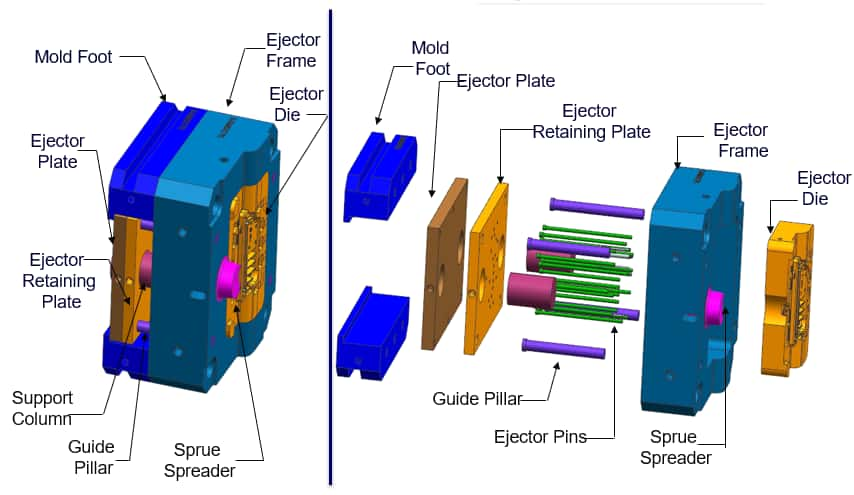

Product molds and tooling design

We can make rubber products tooling or mold according to your drawings. we also have our own CNC workshop to make small to medium size tooling for molding and extrusion products. we calculate and evaluate your needs and give the best cost budget for your tooling investment. you won’t waste money on the tooling making. your rubber molding and extrusion design will have the best result on reasonable cost and best reliability.

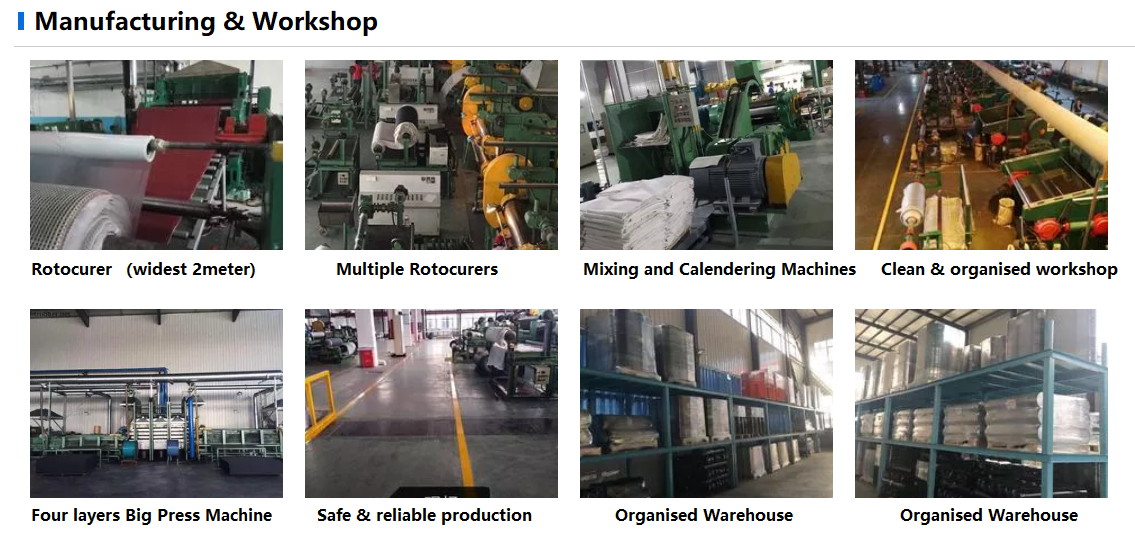

Manufacturing

The production process of rubber sheet should go through the basic processes of plasticizing, mixing, calendering or extrusion, molding and vulcanization, product inspection, packaging, etc., each process has different requirements for the product and use different equipment, and is matched with a number of auxiliary operations such as heating, cooling, testing. The types of rubber sheets are different, and the production process is also slightly different. All these steps will be fully recorded for quality control tracking purpose. therefore all production or any products can be traceable in case of quality claims.

Full Capacity in Our rubber sheet factory Manufacturing Plant

3000+

Items avalability

In 30 years of production, we have made over 3000 items for our clients including rubber sheets, rubber mats, rubber molding parts, rubber extrusion parts and other semi-finished rubber mixing compounds. we can supply finished products and semi finished compounds mixed rubber for you.

1000+

clients in the world

We have served over 1000 clients in the world in last 30 years. before 2000, our main market is in China, after that we explored the rubber sheet and mats products to the world market as an pioneer in China. although lot of Chinese companies lowered the quality for cost pressure, we keep believing the quality is the key to survive in the market. We work with our clients to make best cost and quality balance.

1000+

Containers per year

We almost produce 3 container of rubber sheet per day now from our production base in Nanjing, Tianjin and Baotou city. Our factory is removed from Beijing to other cities due to Beijing government industry relocation planning.

How to Make Rubber Sheet Step by Step

1. Formula Selection and compounding

The first step that is vital in manufacturing good quality rubber sheets is the choice of right formula and process according to technical data sheet. Compounding entails adding various fillers and additives to the raw rubber in order to improve its properties.

2. Mastication and Mixing

Mastication therefore is a mechanical process where raw rubber is reduced in size and at the same time the particles are made to bond better to each other. Later on the masticated rubber compound is mixed to allow proper combining of all other additives that have not been well mixed by Banbury Mixers or Two-Roll Mills.

3. Calendering and Vulcanization

Calendering is the final step where the rubber compound is made into papers of required thickness. On how it is produced, Vulcanization is the process that was said to endure rubber with its characterizing elasticity and strength by Compression Molding and going through a heated tunnel or an autoclave. After cooling, trimming, Inspection, Testing and final inspection, the rubber sheet is packed and labeled for storage and shipment.

After-Sales Service

Service throughout the entire business cooperation 7 days by 24 hours

In all these years, we had helped our clients to develop new business and manage the products sourcing, production, development and shipping projects from drawings to finished products. industries involved in machinery, metal, plastic, rubber and electricity, bags and daily use items. we have strong confidence and rich experience to help you find good and stable quality suppliers and products, secure your market advantages and interests.

Contact us

Need support?

We’re 24/7/365 at your service!

Our Service is at your finger tips. Please let us know what we can help you. Your email will be replid within 24 hours normally. soonest you will get a reply within 1 hour at working hours. We believe fast response is very important for your business. W value your time and opportunity to cooperate.

Inquire us Now