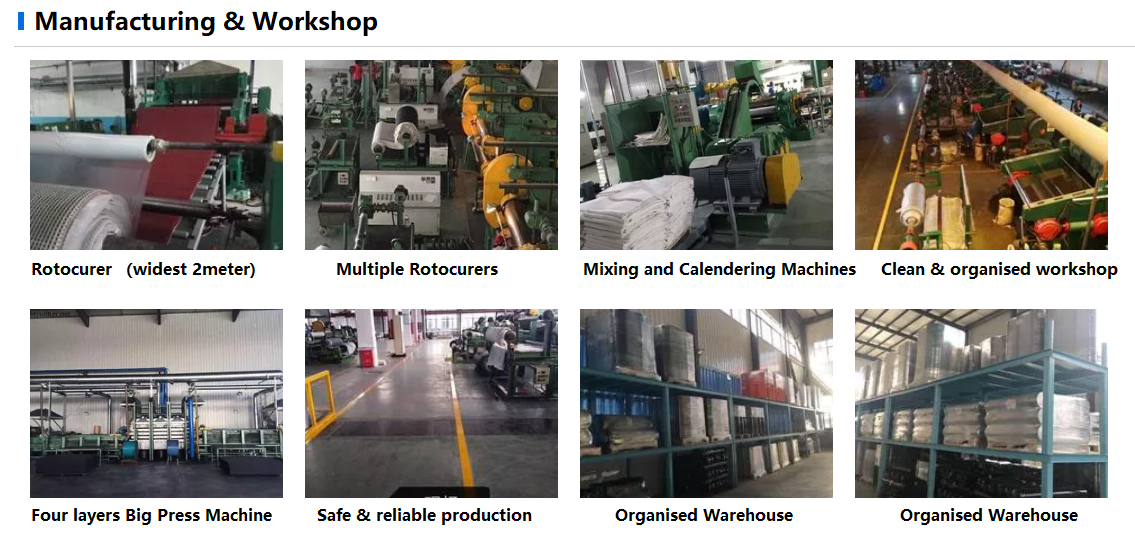

Advanced Roto Curer Machines and Complete Quality Assurance System

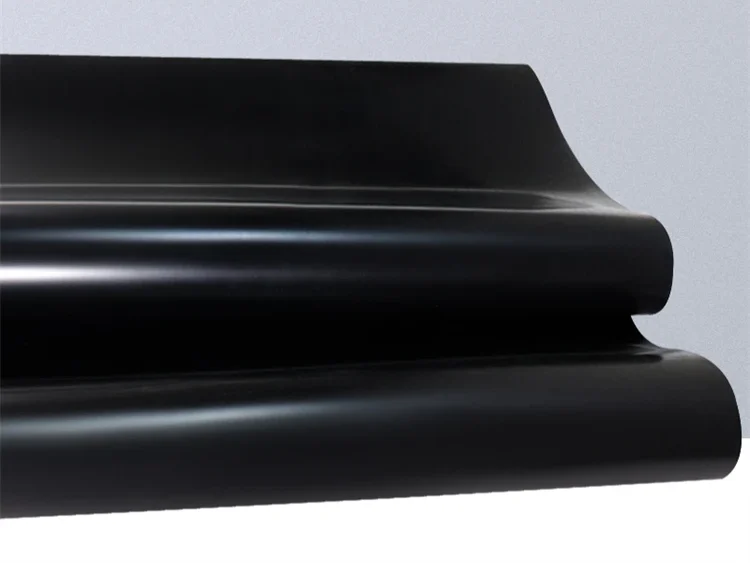

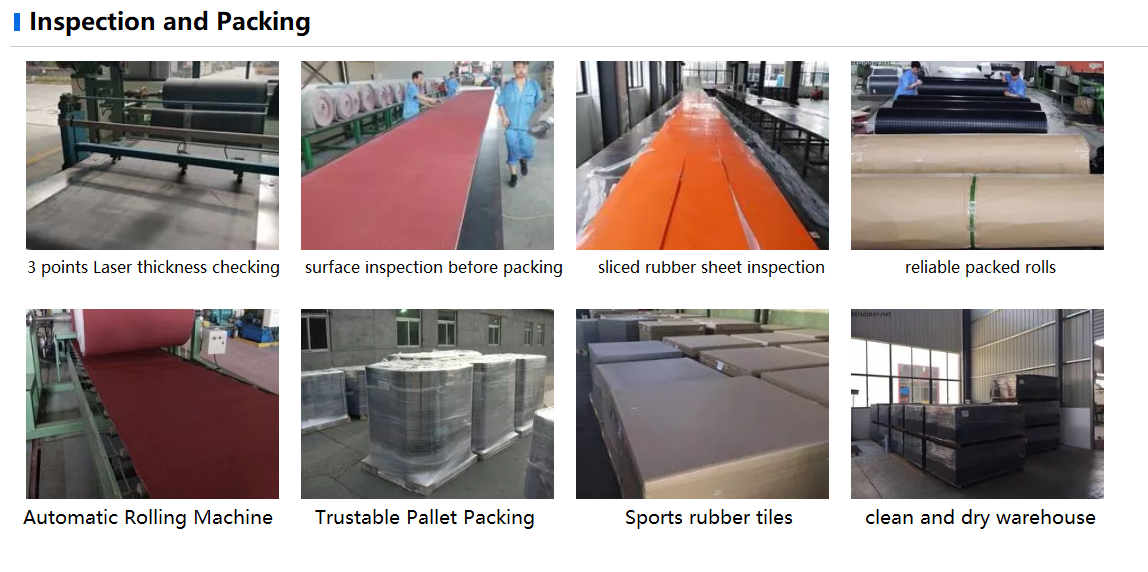

The rubber sheet produced on our advanced roto curer machines with laser thickness gauge online meter are highly accurate on thickness control. it meters the thickness of rubber sheet all the time and adjust the machine to produce qualified rubber sheet for most strict industry standard, therefore the seals from our rubber sheets are assured of excellent sealing.

When it comes to stamping and punching process of rubber seals from rubber sheeting, there is no doubt that the thickness control is an important part of the quality control from the source, besides that the rubber material shall comply to the specification. Our facility controls every step of the rubber sheet production process, all materials have to be magnetic screened to pick out any metal pieces in mixing rubber. As a result, the end users’ stamping machine is well protected from tooling knife being broken by the metal pieces in the bad rubber sheet. Thus your property avoids damage and the breakdown time of your production will be much less.

Each process of rubber sheet production has quality control, and the specimens are taken to lab for testing to make sure the formula will meet the property of rubber sheet as designed and expected by customers. All records are kept for future tracing in case of a quality complain.