Reliable Rubber Sheet Manufacturer

XT rubber and plastic products Co., Ltd. is an expert and leader in rubber sheets and mats factory in China. During our 30 years of development, we have gained a lot of trust and orders from clients around the world. No matter you order big quantity or small quantity, we will serve your needs. XT Rubber sheet producer is a fully integrated manufacturer. Uniquely equipped with a full-service Research and Development laboratory, a team of certified chemists, full mixing capabilities, and over 3,000 rubber compounds on hand, XT Industrial Rubber is well suited to formulate compounds that are specifically designed for your application.

At present, we have strong supply chain support in rubber and plastic sheets and mats products. Our rubber sheets are made of NR, SBR, Neoprene, NBR, EPDM, Butyl, FKM, Hypalon and HNBR, silicone, etc. We also use vinyl, PU, and other plastic elastomers to produce molding and extrusion products. We are looking forward to your visits to our factory, welcome you from any place all over the world!

High Quality Rubber Sheets for All Industries

Types of Rubber Sheets We Made

Rubber sheet for Gaskets

Rubber Sheets for Gaskets require very strict quality standards and tolerance on the dimensions, especially the thickness. We care for your needs and feelings.

Get a free quoteRubber Sheets for Protection

The surface of the industry parts has to be protected from corrosion and collision. Rubber mechanical and chemical property are very much important.

Get a free quote

Rubber Sheet for Engineering

High Quality Rubber sheets are specially made to specialty industry machines. Such as vacuum lamination Process for furniture wood boards and insulation layers bonding of steel tubes.

Get a free quoteGet Your Custom Rubber Sheet

XT rubber is a trusted rubber sheet manufacturer with years of experience in creating high-quality rubber products solutions for various industries. It specializes in manufacturing high-quality custom rubber sheets and mats to cover various needs of customers. Here are your custom selections:

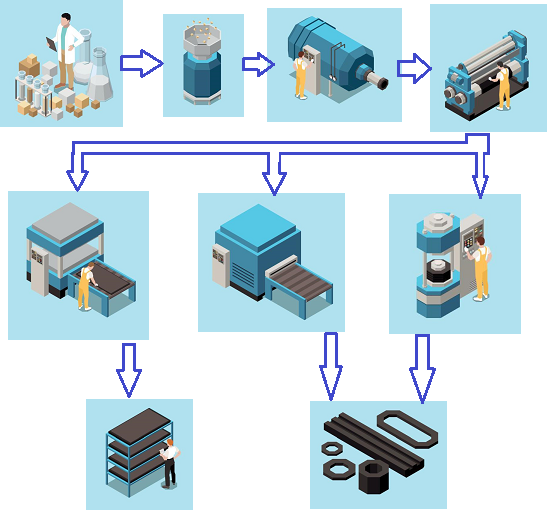

Get A free quoteRubber Sheet Manufacturing Process

1) Weighing Raw Materials: Get the formula and make calculations, Weigh the raw materials ready for rubber compounding mixing process;

2) Mixing Process: Add Raw Rubber and some chemical additives to mixer, The mixer will cut the big blocks of rubber into pieces and blend the rubber with the additives to get a preferred property we designed for the rubber applications.

3) Setting and Calendering: Mix rubber compound is very hot, it must be setting to cool down. the cooled mixed rubber blocks at certain temperature will be put on calendering machine to be processed into different thickness of sheets. the long rolls of calendered sheets will be set aside for vulcanization process by roto curer or press machine; rubber pieces randomly collected will be sent to lab for testing to make sure the mixed rubber will get property we designed for the product.

4) Vulcanization and Curing: The mixed raw rubber sheets are fed into the roto curer which is heated to certain temperature at a specified feeding speed continuously. from one end, at the same time, the finished rubber sheet is produced from the other end of roto curing machine. the trimming and cutting are made automatically on machine. the rolling machine will roll up the rolls automatically. when the length of rubber sheet meet the preset number, the knife on machine will cut the rubber sheet for inspection. The thickness of the rubber sheet is checked all the time by laser gauge sensor during production. the worker will check the finish and thickness every few minutes. defects will be cut from the sheet immediately to make sure only the perfect rubber sheet is delivered to clients.

5) Inspection and Packing: The rubber sheet sample will be collected for physical and chemical tests after the production. If it meets the quality specification, the quality control personal will inspect the dimensions and surface again. some rubber sheets may have to be cut to size, depending on customers’ specific requirements. All qualified rubber will be packed securely with waterproof packing. if pallet packing is required, all rubber rolls and sheets will be packed on strengthened ply-wood pallets by our professional and skilled packing staff.

GET A FREE QUOTE

Rubber Sheet Design Details

Custom Formulation designs include the following:

- Requirement Analysis: The clients talk to us their needs and application of the rubber sheets, our team determine the properties of the rubber sheet, propose several formulas with different chemicals.

- Formula testifying: Ours lab people will work on the formulas on small batch mixing machine, the mixed rubber will be vulcanized on test machine to get production process data, according to the data the production process control data. the rubber property will be tested after the vulcanization to prove the rubber meets designed specification.

- middle scale production: In this stage, the rubber sample for clients will be made o a larger scale on production machines from mixing to vulcanization. when the finished rubber sheet is made, samples will be cut for testing, thus if the rubber property meet the expected specification, the sample will be sent to clients for confirmation.

- Place Orders: If the sample and prices sent to clients passed the tests at clients’ lab and application tryout, the clients can place the real order. We will produce according to the standard production procedures.

Rubber Sheet Benefits

- Sustainability: Rubber and plastic can be recycled and reuse. It helps good sealing of machinery and protects equipment to prevent energy losing and pollution, keep safe working. Rubber and plastic are renewable and recyclable;

- Customization: Rubber Sheets offer various customization options (i.e., Chemical and Oil Resistance, Noise and Vibration Reduction, Enhanced Slip Resistance, Superior Impact Resistance, fire retardant, thermal Insulation Properties, color, shape, material, design, with logo, and size);

- Cost-effectiveness: a well-designed rubber sheet is a cost-effective industrial solution for businesses of all sizes.

- Excellent Durability and Longevity: Rubber sheets are well-known for their outstanding durability and extended lifespan, making them perfect for industrial settings where resilience is crucial. Their capability to endure tough conditions, abrasion, and wear provides extended protection for both equipment and surfaces, thereby reducing the necessity for frequent replacements.

Rubber Sheet Application

Rubber sheets, strips, and rolls are used for sealing, absorbing impaction, protection and formed into custom gaskets. Recycled rubber reduces waste and protects the environment. SBR rubber is flexible and abrasion-resistant. Silicone rubber tolerates high and low temperatures. Viton rubber resists harsh chemicals, oils, and high temperatures. Viton sheets and strips are commonly used to fabricate gaskets, seals, and liners in chemical processing and petroleum applications. Butyl rubber is impermeable to air, moisture, and gas. EPDM rubber is used for weatherstripping, padding, and liners. Flurosilicone rubber withstands fuels, chemicals, and solvents and is used in the aerospace industry. Buna-N rubber resists oils, fuels, and petroleum-based hydraulic fluids. Hypalon rubber insulates wires, cables, and sensitive equipment. Natural elastic rubber is flexible and abrasion-resistant. Neoprene rubber resists refrigerants and is commonly used in air conditioning systems. Polyurethane rubber has excellent tensile strength and tear resistance. Vinyl rubber is durable and resists chemicals. Viton rubber is used to fabricate gaskets, seals, and liners in chemical processing and petroleum applications.

Rubber Sheet for Food Industry

Food grade rubber sheet products are made with FDA Approved ingredients. These products meet the 21 CFR 177.2600 FDA regulation that deals with rubber articles intended for repeated food exposure. Our FDA products may be safely used in producing, manufacturing, packing, processing, preparing, treating, packaging, transporting, or holding food.

FDA sheet products are available in Neoprene, Nitrile (Buna N), Viton® & Fluorozone Fluoroelastomers, Red Silicone, Natural Rubber, Pure Gum Floating Natural Rubber and Black & Neutral Thermoplastic.

Rubber Sheet for protection

Protection of Work Surface – Rubber in rubber sheets is very useful since it is a very good cushion or bump stop in many cases. Because it is elastic, it can protect several work surfaces in industrial environments from damage. It can be sued as work flooring, pipe or tube lining for chemical industry, mining equipment and shot blast chamber in surface treatment process.

Protection of Machines – Rubber is the ideal choice of material when it comes to protecting your equipment. Rubber is a shock absorber.

Protection of Personals – Di-Electrical Rubber is the ideal choice of flooring material in the electrical Safety places. Rubber sheet comply to EN 61111 can be used to protect workers safety in electricity workplace.

Rubber Sheet as vacuum part in process for Industry

Rubber sheets are widely used in various applications due to their exceptional properties, such as high temperature resistance and elasticity. These sheets are perfect for thermal forming, hot pressing and vacuum forming of solid surfaces, as well as other composite materials. Their versatility ensures that these rubber membranes can be used for multiple areas.

Especially the silicone vacuum sheets are used in woodworking businesses around the world. It is ideal for 3D lamination application. It is also used for pipes protective coating layer lamination process when it is glued into a rubber sleeve.

Rubber Sheets in Garment Industry

The high quality latex sheeting for the fashion industry has always been made from the FDA safety ingrediencies, and strict adherence to ISO Manufacturing Guidelines. In this growing and exciting market we have become the supplier of choices to some of the world’s leading designers and artists, we are constantly developing our range to meet our clients needs. We aim to help our clients to convert their ideas to real products, such as ideal finishes and thicknesses and if it isn’t in our range we will try to make it for you. We use only the very highest grades of raw materials and have very stringent quality control to ensure that our materials are of the highest quality. If you need help, can’t find what you’re looking for or have an interesting idea for latex material please don’t hesitate to contact us.

Why Choose Us as Rubber Sheet Supplier

Professional and Advanced Equipment

With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice. Advanced equipment creates high-quality products for you.

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Improve product sales and technical after-sales service. 24 hours online video call, actively solve problems for customers

What Our Other Customers Say About Us

After-Sales Support

1. Help Desk and Technical Support Services

Such after-sales support may come free with the purchase of an item and may also be sold as part of a more comprehensive service plan, such as complicated products testing in third party labs for certification reports. you can send us email or phone call to our sales people.

2. Real-Time Online Support

Real-time online support includes email, chat, forums, and a social media interface (and monitoring) that assists in responding to public complaints and criticisms. This may include handling returns or repairs. we welcome your contact and suggestion to improve our service and develop new ideas.

Rubber Sheet production FAQs

W are an ISO 9001 and ISO 14001 certified rubber sheet and mat manufacturer since 2000. Our company was originated from daughter companies of Beijing Chemical Industry Group, it was a merging of Beijing Number 5, and No. 10 rubber factories. These two factories had started rubber sheets since 1950s. Due to new industry planning changes in Beijing, we have moved our production center to Hebei, Tianjin and Nanjing cities.

Rubber Sheeting by Material

Rubber Sheets By Dimensions

- long rolls: this is the most common shapes we made to order.

- flat plates: press made by pieces by order

- sliced pieces in long strips: sliced long trips of rubber for conveyer belt skirt use,

- block: cut in thick blocks for special purpose

- Blades: cut in size for snow blades or floor squeegee rubber

- thin sheets for clothing: rubber sheets as thin as 0.5mm for rubber fetish clothing garments industry.

- belting types: this as cut in size for belting use for machines

- vacuum lamination sheet, this is made to size for lamination machines of furniture parts or boards

- We also accept customized shapes. Please contact us if you’re interested.

Rubber Sheets By Usage

Applications of Rubber Sheet

Rubber sheets, with their diverse material compositions, find extensive applications across a broad range of professional industries, catering to unique needs and challenges. The choice of rubber sheet is vital, and different types are selected based on their properties. Here’s an insight into how rubber sheet materials are used across different industries:

Automotive & Motorsport

In the automotive and motorsport industry, rubber sheets play a crucial role in ensuring performance, safety, and longevity. Neoprene and Nitrile rubber sheets are commonly used for gaskets and seals, providing resilience against oils and chemicals. Nitrile rubber sheets, known for their exceptional oil resistance, find applications in engine components, fuel systems, and conveyor belts.

Aerospace & Defence

In aerospace and defense applications, where exposure to harsh conditions is inevitable, specialised rubber sheets are employed. Viton and Fluorosilicone rubber sheets excel in this domain, particularly in fuel systems. Their superior resistance to volatile fuels, oils, and chemicals ensures reliable performance in critical aerospace components.

Food Production & Processing

The food production and processing industry demands rubber sheets with high hygiene standards. Silicone rubber sheets, commonly FDA approved, are extensively used for manufacturing kitchenware, bakeware, and seals in food processing equipment. Their non-reactive nature and ability to withstand extreme temperatures make them ideal for food-related applications.

Medicine & Pharmaceutical

Rubber sheets find applications in the medical and pharmaceutical fields due to their biocompatibility and flexibility. Silicone rubber sheets are often used in medical devices, seals, and components. Their compliance with stringent medical standards and flexibility make them suitable for various healthcare applications.

Construction Industry & Industrial Applications

In the construction industry and industrial applications, rubber sheets contribute to sealing, insulation, and protection. EPDM rubber sheets, renowned for their weather resistance, are commonly used for outdoor applications. Natural rubber sheets, with their flexibility and cost-effectiveness, find applications in conveyor belts and industrial hoses.

We use high-quality rubber materials such as Neoprene and Nitrile to EPDM, Silicone, Viton, Natural Rubber, Butyl, HNBR, FKM, CSM, PVC, peroxide EPDM, Peroxide cured Nitrile Rubber and Fluorosilicone, each variant offers distinct properties catering to specific needs. For example, we developed BS 1152, IEC 61111, BS 921, BS 2752, BS 2751 rubber sheets for our clients.

We offer a variety of standard dimensions for our rubber sheet, including strips, imperial, and metric sizes. However, we can also provide custom sizes as per the specific requirements of our customers. normally width 1m, 1.2m, 1.4m, rolls length is 5m and 10 meters. thickness range from 0.5mm to 50mm. specially we make 90mm in thickness.

Yes, we can provide custom sizes for our rubber sheets. Our team of experts can work closely with customers to determine the appropriate dimensions based on their unique needs. we offer different thickness options for our rubber sheet based on customers’ order requirement. Customers can choose the appropriate thickness level based on their specific needs.

We offer a range of formula development options for our rubber sheet, including wear resistance, oil resistance, Chemical resistance, fuel resistance, fire resistance, flame resistance, slip resistance, sound proof, electric voltage proof. Customers can also choose colors, patterns, depending on their design requirements.

Yes, we offer test report for our rubber sheet based on customers’ requirement. Customers can choose the appropriate physical property and Chemical property tests based on their specific needs. the test cost will be charged if third party lab test report is asked.